Srivardhan Khemka is the director at Sanjivani Paranteral Ltd , a pharmaceutical manufacturing company based in Mumbai & a second generation entrepreneur in his family business.

He transitioned from:

– manually managing daily operations.

– using separate workflows that didn’t fully connect all the business operations.

– struggling to find time to focus on long-term planning as the director.

to:

– stepping away from daily operations.

– simply checking reports to ensure the team’s performance.

– dedicating more time to plan for business development and the future of the company.

How How did this transformation happen?

We built a custom app using Glide to streamline his manufacturing company’s operations. The app includes features like inventory tracking, automated purchase order creation, order management, and automatic report generation.

This not only helped Srivardhan but also benefited the entire company by improving efficiency and productivity. Employees now experience more structured workflows, leading to smoother operations and reduced manual workload.

Tech involved: Glide, Google Sheets, Google Apps Scripts.

Sanjivani is a pharmaceutical manufacturing company & a family business, based out of Mumbai. It was started by the father of Srivardhan, Ashwani Khemka, 30 years ago.

They create life-saving medicines used in the ICU & are majorly focused on exports across the world. They continuously identify the most pressing unmet healthcare needs, so they can be the first to deliver products and solutions that lessen the burden of disease.

They are a listed company on the stock exchange with 140+ products & operations across 25+ countries. Their USP is their quick lead time, 30-35 days, while the market standard is 60-90 days.

Srivardhan’s role in the family business was to manage operations & grow the business in newer markets.

From Mar 2020 to Nov 2022, they grew from 2 factories to 12 factories and 140+ products. Many mistakes & losses were happening because of this sudden growth.

He started facing the following problems as the business grew:

1. The lack of a connected workflow: It meant each department operated in isolation. Once one department completed its task, manual intervention was required to inform the next department to begin their work. This often led to delays and inefficiencies. Srivardhan was doing this manual intervention most times.

2. Deficit of free time: He had to focus extensively on current operations, leaving little time for strategic planning, business development, or even personal health. The lack of time hindered the ability to pursue new leads or innovative business ideas, crucial for future growth.

3. Randomly incentivising the team: Incentives were given randomly based on subjective judgments of performance. There was no clear tracking system to measure the time and effort employees spent on their tasks, leading to potential dissatisfaction and reward inconsistency.

There was no workflow linking all our operations. Once a department finishes their work, it would require me to come in and tell the next one to get on with their job it was repetitive time consuming and draining. I didn't have the free time to focus on the next future vision of the company.

For him, the idea of software was ERP which would be expensive, and the implementation would not be perfectly done. Thus the money will go to waste. ERPs implementation is also pretty standardised, as you have to bend your processes to fit the software. But Srivardhan wasn’t ready to change his company’s processes to fit a software. So he was not willing to solve these problems via a traditional ERP system.

They were just dealing with the pressure and they thought that it would eventually streamline. He was not looking to solve this problem initially.

Srivardhan has known me since school & he was actively seeing my content on LinkedIn about helping my clients solve operations problems by building custom apps with NoCode tools like Glide.

So, he decided to discuss these problems with me & I proposed building a completely customized internal app with Glide to solve these problems.

He wanted to make his USP, quick lead time, scalable through this digital app. Because he didn’t want to be in a situation where once they scale up to a larger audience, they get stuck because of manual processes with no workflows.

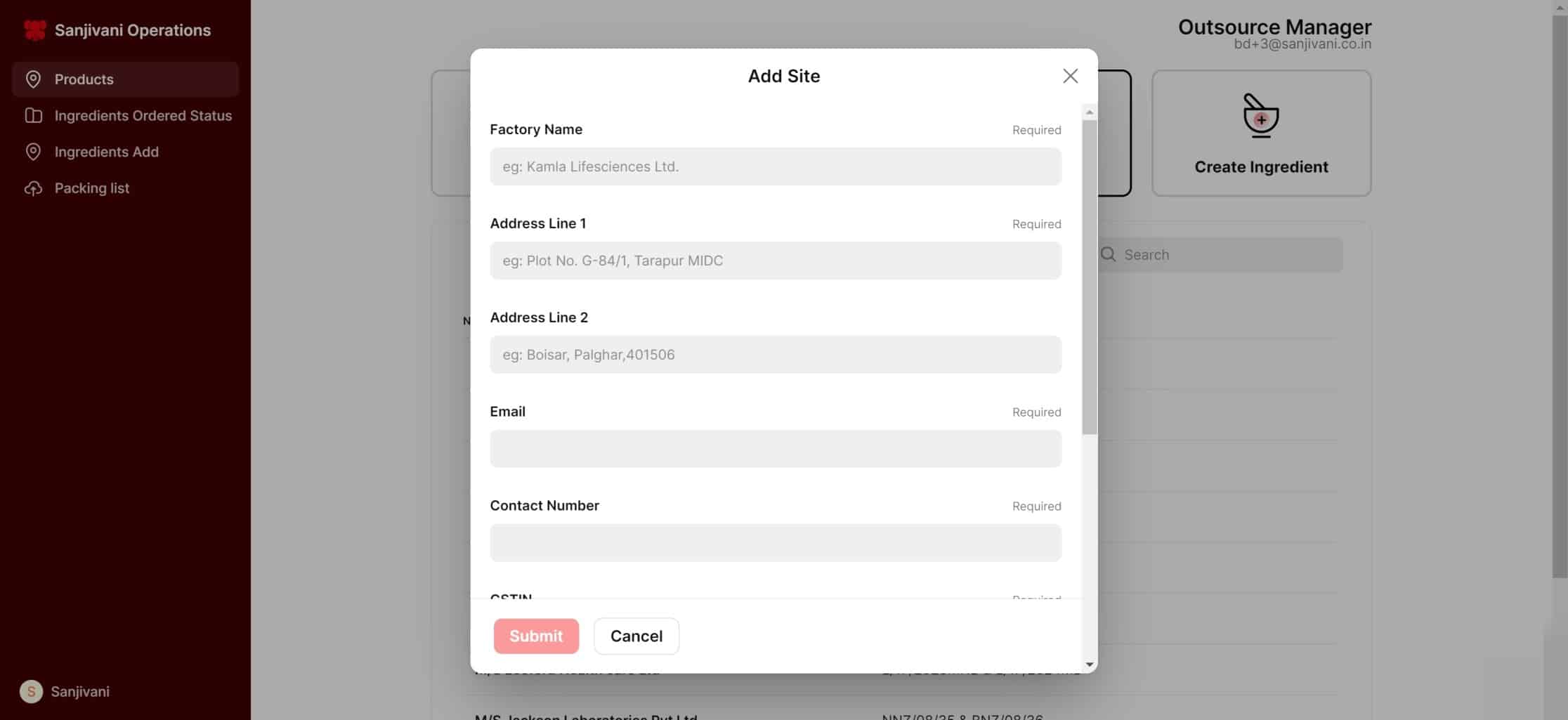

We started working together by building a project architecture phase where we documented their processes to be automated.

We built the following important features for Sanjivani:

1. Live inventory tracking: They are a listed company. They need to track everything. For each order of a specific product, they use unique ingredients. With this feature, they can see the live status for each order and each ingredient linked to that order. Earlier, they used to coordinate manually for this & used to prepare an Excel sheet. It used to take a lot of time for them. Now, it is all automated.

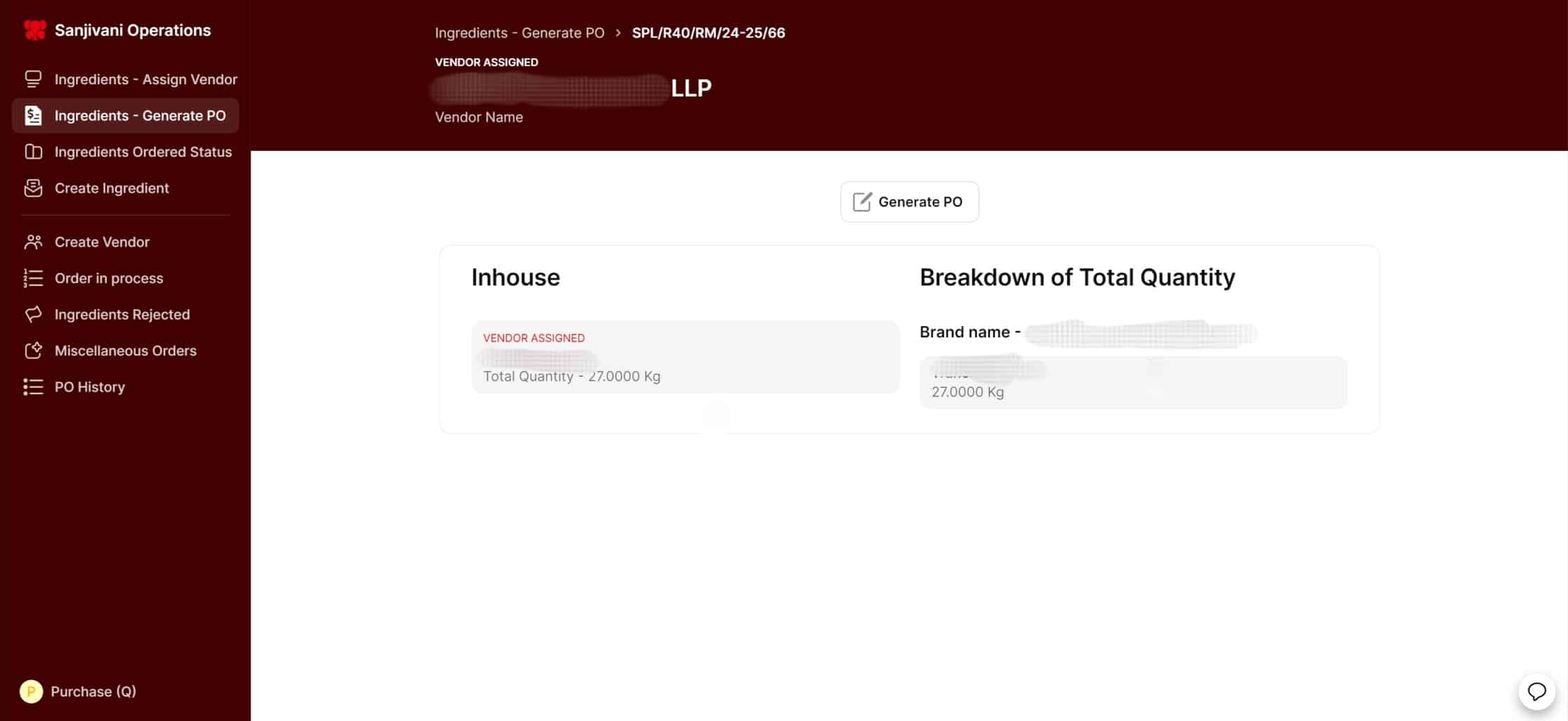

2. Automatic generation of purchase orders (P.O.) & its numbers: This feature again works at both ingredient & order level. Earlier, they had a pre-set template where they had to fill in the details manually for the generation of P.O. Now, at the click of a button, a P.O. in the form of a PDF is generated for them automatically.

Earlier, it was a manual effort to number Purchase Orders by following a sequence. Now, it is created automatically.

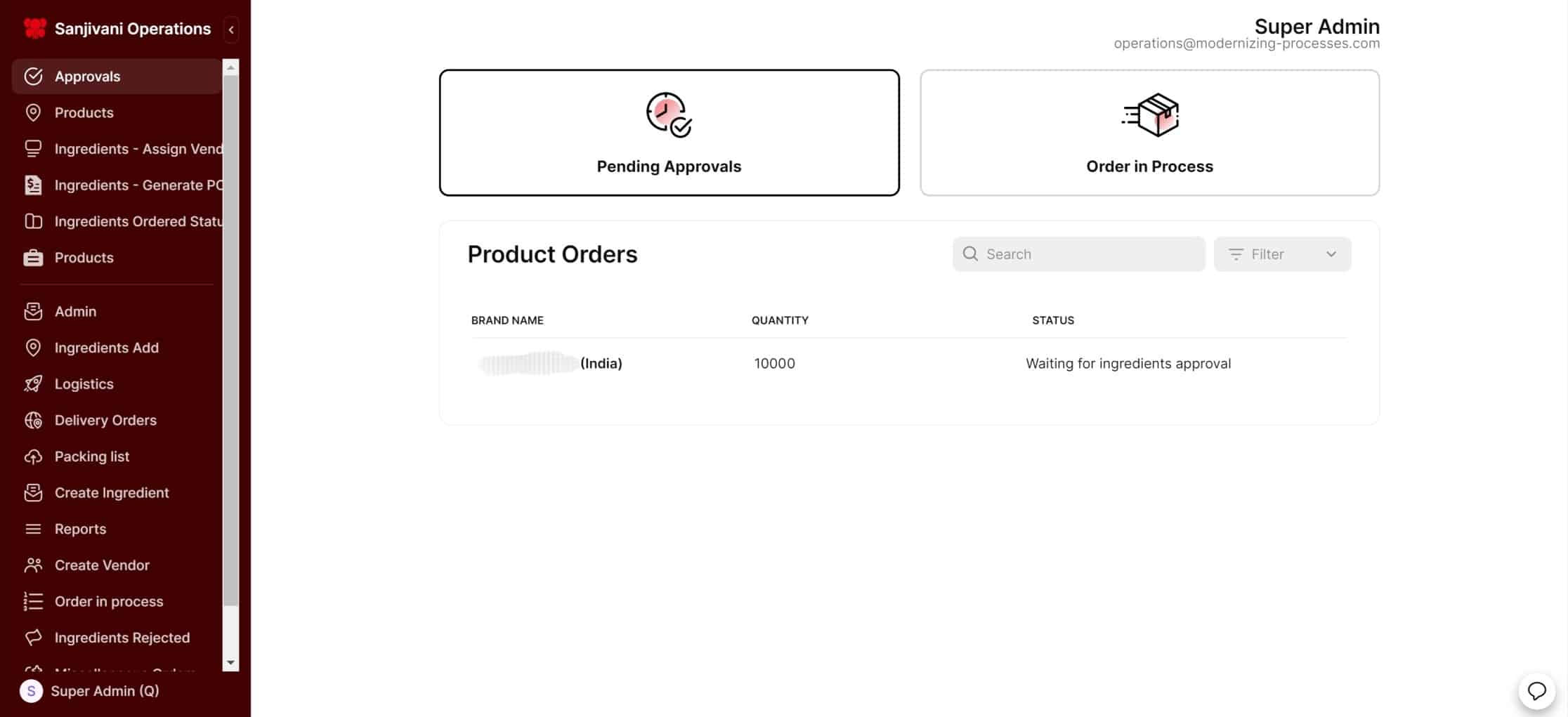

3. Reports: We built 2 kinds of reports for them. One kind is an automated report at 9 AM every day. It is a high-level report which helps them understand where ingredients are stuck concerning a specific order.

The other kind is reports generated at the request of the admin. It can be bifurcated based on the order journey, vendor reports, user reports, and delivery status reports of multiple batches of a specific order.

4. Filters & View for data-driven decision making: Presenting multiple data & letting users segregate them using different filters for better decision making.

e.g. The purchasing team has the responsibility to procure ingredients linked with all orders. Now, one ingredient can be used for multiple orders, so a grouped quantity is displayed on an ingredient-level view.

When an order is placed, multiple ingredients are linked with an order, so on the product level, you can check how many ingredients are to be procured. Similarly, on the ingredient level, you can check the total quantity which needs to be procured & in which products that ingredient is going to be used.

I have 3 orders. Order X includes ingredients A, B, and C. Order Y includes ingredients A & B. Order Z includes ingredients B & C.

So when they check on a product level, they see Order X is having 3 ingredients (A ,B, C), Y is 2 ingredients (A, B) & Z is having 2 ingredients (B, C). If they check on the ingredient level, they see ingredient A is required in 2 products (X, Y) & its cumulative sum, ingredient B is required for 3 products (X, Y, Z) and its cumulative sum, and ingredient C is required for 2 products (X, Z) and its cumulative sum.

It helped them to know the total ingredients for each product in procurement. So they can negotiate a better price by doing a bulk quantity order.

5. Automatic Closure of Order Journey: Earlier, they used to manually close the order journey when all the batches of an order were created. Now, the system has become smart enough to understand it & close it.

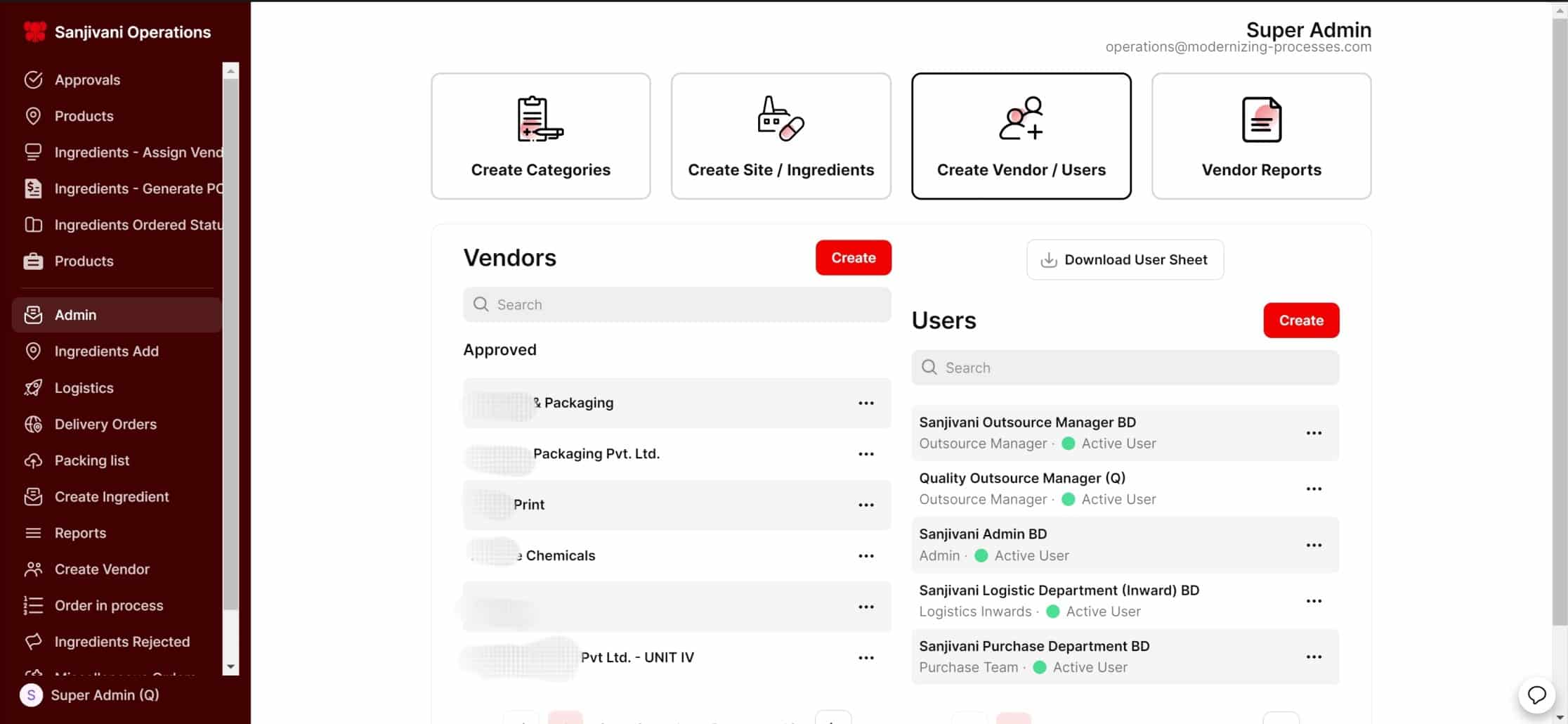

6. Multi-ingredient approval (Super-admin feature): They can approve all, or approve selected or approve one at a time ingredients of all orders.

The business has scaled where they are catering to multiple orders simultaneously, so approving each ingredient one by one was a manual & time-consuming task. Thus, this feature is helping them save time.

e.g. One order has 10 ingredients & to approve each will take a total of 5-10 minutes. But the new approve all or multi-select approval would at most take 1 minute. Hence, if we compare this number on a big scale, it is saving hours of work every day.

(We have blurred few parts in the screenshots to maintain the confidentiality of client’s crucial internal data.)

With the app in place, the following changes happened:

They have been using our app for the last one year. The app empowers them to maintain their USP a quick lead time without facing mistakes or losses. They have been able to focus on growing the top line while the app takes care of the bottom line.

The app is saving us 30% of the time which was spent on manual operation. This has allowed me a lot of free time to not only focus on business development but my health and travel and more over on the company's future.

They save 30% of the time previously spent on manual operations by using the app. For a company of Sanjivani’s scale, a 30% time savings is incredible, and we aim to increase it even further by incorporating even more technology into their business operations.

We never thought our operations could be streamlined in such a digital manner and at such a cost-effective value using NoCode. I really thank Manan and the Modernizing Processes team for this.

If you are a business owner who is facing workflow & automations problems like Srivardhan, book a discovery call with us with the following link to discuss your project.

Let us modernize your internal business operations, save your time as a business owner and help you achieve your business goals.

Sanjivani Paranteral Ltd Contact Details: https://www.sanjivani.co.in/

Don’t miss our future updates! Get Subscribed Today!

©2024. MS CUBE SYSTEMS PRIVATE LIMITED. All Rights Reserved. Designed with ❤️ by Digital Consulting Pandit

WhatsApp us